*All Products Available for Purchase or Daily Rentals

Sand Barrels

Sand barrels or “sand attenuators” are used primarily at bridge abutments, cantilever posts, gore areas and at barrier wall-ends and are simple to move and install (certified to meet the crashworthy requirements of NCHRP 350). Sand barrels absorb the energy of a crash and reduce collateral damage to other vehicles and injuries to traveling motorists.

K&S Industries can provide different configurations, styles and weights to meet customer needs. Installation and removal services are available. Please contact a local K&S Industries branch for more information.

Crash Cushions

K&S Industries is distributor for leading manufacturers who offer both fully redirective and non-redirective crash cushions approved for use in permanent and work zone applications. All crash cushions meet the crashworthy requirements of NCHRP Report 350 and are approved for use on the national highway system.

Redirective crash cushions

- Non-gating, and bi-directional

- Ideally suited for roadway hazards such as the ends of rigid barriers, tollbooths, utility poles, etc.

- Designed for maximum safety and reusability

- Outstanding durability before, during and after an impact

- Easy installation

- Low-profile foundation

- Transition options

- Low maintenance requirements, and reusability of system components

- Ask us about our resettable crash cushion—a revolutionary product that is changing the industry!

Non-redirective crash cushions

- Narrow, anchorless, water-filled crash cushion suited for multiple speed conditions with its modular technology

- Can be deployed on almost any road surface

- Rapid deployment and retrieval

- Ideal for contractors due to ease of maintenance after impact

- Dozens of transition options available

- Can be used in cold weather

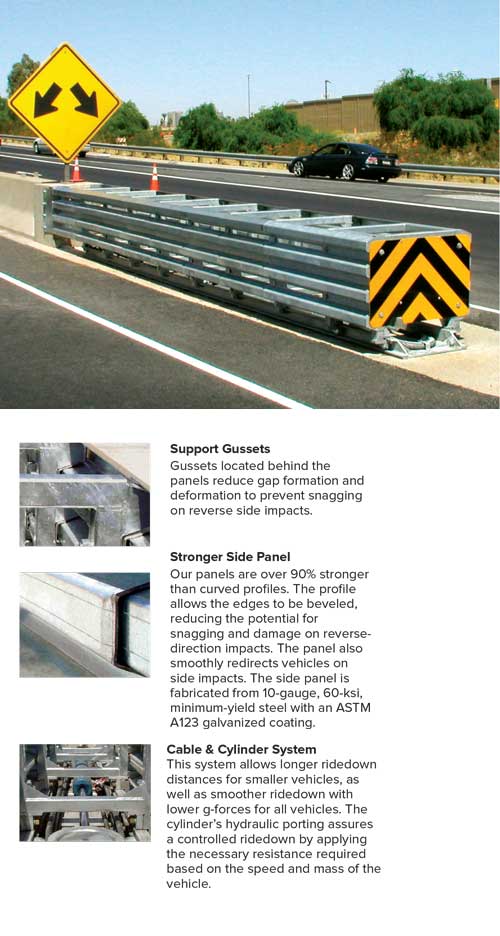

Smart Cushion

The Smart Cushion® crash attenuator is a revolutionary, speed-dependent product that varies stopping resistance during an impact. The Smart Cushion® crash attenuator allows lighter and slower-moving vehicles to have longer ridedown distances and lower ridedown g-forces.

Unlike fixed-resistance attenuators, the Smart Cushion® attenuator does not reach maximum stopping resistance unless a vehicle is traveling at the maximum design speed. This fully redirective, non-gating, bidirectional, impact attenuator was designed for maximum safety and reusability, as well as outstanding durability before, during and after an impact.

The Smart Cushion® is the only attenuator with a reverse-tapered design to eliminate side panel stress during a collapse. It also has an extremely low angle of exit on side impacts (<1°) to keep vehicles from rebounding back into traffic and causing secondary accidents. This is the lowest angle of exit for any redirective attenuator on the market.

How It Works

The hydraulic porting of the attenuator ensures that the proper resistance is used to stop the vehicle before it reaches the end of the cushion’s usable length. The Smart Cushion® was specifically designed for durability and resetability to enable resets to be performed in less than 30 minutes. Side impacts within NCHRP 350 specifications do not damage the attenuator.

After an impact, the cushion requires a dual-stage pull-out with the replacement of two 1/4” shear bolts. The crash attenuator requires a minimal inventory of spare parts because of the new side panels’ durability and the normal requirement of only two shear bolts on the frontal impact reset. Minimal damage means quick resetting and reduced worker exposure to traffic, as well as lower costs for traffic control, replacement parts and labor.

Ready To Install

Smart Cushion® attenuators come fully assembled for a pick-and-set install. A typical installation can be performed in less than 90 minutes. The Smart Cushion® is self-supporting and requires no additional support for permanent or temporary construction applications.

NCHRP 350 Test Results

All NCHRP 350 tests were performed on the same unit over four consecutive days. All tests showed outstanding results for ridedown g-forces and low angle of exit. There were no replacement parts required prior to the next test except for shear bolts.

- Smart Cushion Innovations®

- MASH Approved

- NCHRP 350 Approved

- The World’s Only Speed-Dependent Crash Attenuators

A COMPLETE FAMILY OF REDIRECTIVE, NON-GATING CRASH CUSHIONS TO SHIELD ALMOST ANY HAZARD

The Redirective, Non-Gating, Universal TAU-II Crash Cushion Family consists of a full line of Impact Attenuators designed to meet the requirements of NCHRP Report 350, TL-2 & TL-3. This family of crash cushions is available in lengths and capacities for both low and high-speed applications from 50-113 km/h (30-70 mph). The TAU-II Family of Crash Cushions can shield hazards with widths up to 2.6 m (102”).

TAU-II Non-Gating Redirective Systems are ideally suited for roadway hazards such as the ends of rigid concrete barriers, steel barrier, bridge piers, signs, etc.

RESOURCES

A mobile-friendly installer’s guide is also available. The Lindsay Guide App provides resources for teams installing or inspecting Lindsay Transportation products. Each product section contains video demonstrations of proper installation techniques, text supplements when the video is unavailable, and final checklists.

The Lindsay Guide Mobile App is available for Apple and Android devices, or online.

Truck Mounted Attenuators

Truck Mounted Attenuators (TMA) are ideal for use in high speed lane closures or mobile operations where workers are most vulnerable.

K&S Industries’s low-profile TMAs have an open tubular design to minimize wind resistance and drag allowing for safe travel. The hydraulic system allows the TMA cartridge to be partially raised for maximum roadway clearance and maneuverability. TMAs crush in progressive stages upon impact absorbing much of the energy of crashes. TMAs provide protection for roadway workers and traveling motorists as well as reducing collateral damage to other vehicles. With the TMA’s durable construction and heavy duty tubular side rails, incidental back-up or turning damage is minimized. The unique curved design redirects side angle impacts away from the exposed corner of the truck.

This TMA is NCHRP 350 tested and approved

Scorpion Trailer TMA System

The Scorpion Trailer Attenuator attaches directly to a truck’s pintle hook. It does not require additional installation, or truck modification, beyond standard factory installed pintle hook and 1/2″ steel frame plate. Upon impact, two heavy-duty anti-rotation arms are driven against the frame plate, preventing angular rotation of the Scorpion Trailer during an accident.

Features/Benefits

- NCHRP 350 tested and approved for all mandatory and optional offset and angled impacts

- Single-point attachment to standard 20 Ton (minimum) rated pintle hook is quick and easy

- Requires little or no modification to host vehicle or additional mounting hardware. 1/2″ thick x 32″ wide minimum pintle hook mounting plate required

- Telescoping Anti-Rotational System (TARS™) minimizes Scorpion Trailer rotation during angled impacts and prevents trailer separation from host vehicle

- The Scorpion’s proven modular design crushes in progressive states allowing quick and economical replacement of damaged parts

The unique curved design gives full width protection to the back of the host vehicle and protects the “coffin corners” of the truck - Rear axle placement improves trailer stability and prevents the tail from “bottoming out” on driveways or uneven surfaces

Overall length of the Scorpion Trailer Attenuator is only 17′ 5″ – the shortest on the market - Integrated electric brake system comes standard on Scorpion Trailer – brakes are automatically activated in the event of trailer separation or hitch failure

U-Mad TMA

U-MAD Truck Mounted Attenuators (TMAs) offer outstanding performance and quick, simple refurbishment. The U-MAD TMA is available as a TL-2, TL-3 or 80 km/h System for use in work zones with speed capacities from 70- 100 km/h (44-62 mph). The U-MAD TMA provides a wide range of protection for workers, motorists and equipment. The U-MAD TMA has passed the rigorous NCHRP 350 TL-2 and TL-3 criteria for both mandatory and optional tests with an arrow/message board installed. The U-MAD is also available in an NCHRP 350 TL-1 design.

FEATURES

- Only the cartridge needs to be replaced after a design impact

- Passes all mandatory and optional NCHRP 350 TL-2 and TL-3 tests with an arrow/message board installed.

- Engineered to keep the impacting vehicle and support vehicle in the travel lane even after angle impacts

- Cartridges are interchangeable with the U-MAD Trailer TMA, reducing inventory costs

- Light weight design

- Many flexible mounting options

- Optional cab-mounted controllers

SPECIFICATIONS

- Classification – TMA

- Length – 4.19 m / 13’-8”

- Width – 229 cm / 90”

- Height in Storage Position – 381 cm / 12’-6”

- Weight – 590 kg / 1300 lb.

- Test Level – NCHRP 350 TL 1 / 2 / 3

U-Mad Trailer TMA

TL-2 & TL-3 TMA PROTECTION IN A REUSABLE DESIGN

U-MAD Trailer Mounted Truck Mounted Attenuators (TMAs) offer outstanding performance and quick, simple refurbishment. The U-MAD TMA is available as a TL-2, TL-3 or 80 km/h System for use in work zones with speed capacities from 70- 100 km/h (44-62 mph). The U-MAD TMA provides a wide range of protection for workers, motorists and equipment. The U-MAD TMA has passed the rigorous NCHRP 350 TL-2 and TL-3 criteria for both mandatory and optional tests with an arrow/message board installed. The U-MAD is also available in a NCHRP 350 TL-1 design.

FEATURES

- Only the cartridge needs to be replaced after a design impact

- Passes all mandatory and optional NCHRP 350 TL-2 and TL-3 tests with an arrow/message board installed.

- Engineered to keep the impacting vehicle and support vehicle in the travel lane even after angle impacts

- Cartridges are interchangeable with the U-MAD Trailer TMA, reducing inventory costs

- Light weight design

- Many flexible mounting options

- Optional cab-mounted controllers

SPECIFICATIONS

- Classification – TMA

- Length – 4.19 m / 13’-8”

- Width – 229 cm / 90”

- Height in Storage Position – 381 cm / 12’-6”

- Weight – 590 kg / 1300 lb.

- Test Level – NCHRP 350 TL 1 / 2 / 3

End Treatments

An end treatment is a device designed primarily to treat the end of a longitudinal barrier. The end treatment may function by (a) decelerating a vehicle to a safe stop in a relatively short distance, (b) permitting controlled penetration of the vehicle behind the device, (c) containing and redirecting the vehicle, or (d) a combination of a, b, and c.

End Treatments

SLED

The Sentry Longitudinal Energy Dissipater (SLED) is a narrow, non-redirective gating crash cushion. SLED is designed to shield the end of all permanent and temporary portable barrier shapes including concrete, steel and plastic. SLED’s unique design incorporates four internal steel cables which help envelop the impacting vehicle, reducing the possibility of secondary accidents. The SLED End Treatment does not require foundation anchor bolts to be attached to the road or bridge deck. The complete crash cushion can be installed quickly, with as little as one pick up truck and two workers on compacted dirt, gravel, decomposed granite, asphalt or concrete.

Features/Benefits

- MASH Approved

- FHWA accepted for shielding the blunt end of concrete, steel and water-filled barriers

- Quick and easy set-up; no foundation anchoring; minimized installation exposure time

- Cost-effective end treatment for concrete, steel or water- filled barriers

- Universal transition quickly and easily attaches to a variety of barrier shapes and sizes

- SLED’s stout design virtually eliminates vaulting

- Narrow footprint is ideal for work zones or roads with minimal shoulder spacing

- Shortest length TL-3 water-filled crash cushion; fewer incidental impacts

- Visual “Drive By” fill indicators quickly verify water modules are properly filled

- FHWA accepted for use in uni- and bi-directional applications

Absorb 350

For over 10 years contractors around the world have considered the Absorb 350 System to be the optimum portable crash cushion choice for use in work zones. No ground anchoring, the largest selection of transitions and modular technology allow the ABSORB 350 to be used in multiple speed conditions. Contractors appreciate the ease of maintenance after an impact because the ABSORB 350 crash cushion consists of only three different parts.

FEATURES

- Easily transitioned to multiple widths and shapes of concrete and steel barriers

- Meets NCHRP 350 TL-1, TL2, TL-3 test criteria

- Rapid deployment and retrieval

- Can be used in permanent installations

- Versatile modular design

- Narrow footprint

- No ground anchoring required

X-LITE END TERMINAL

The Redirective, Gating, X-LITE Guardrail End Terminal features excellent impact performance. Utilizing superior engineering design, the X-LITE Guardrail End Terminal provides maximum interchangeably for flared and tangent roadside applications. This results in significant savings in inventory, repair and maintenance costs.

The X-LITE Terminal uses many standard guardrail components and is available with steel posts and wood or composite blockouts.

A mobile friendly installer’s guide is also available. The Lindsay Guide App provides resources for teams installing or inspecting Lindsay Transportation products. Each product section contains video demonstrations of proper installation techniques, text supplements when video is unavailable, and final checklists.

The Lindsay Guide Mobile App is available for Apple and Android devices, or online.

FEATURES

- Maximum interchangeability between tangent and flared applications

- Lightweight impact head

- Available as a kit or system

- 710 or 790 mm (28 or 31”) height option

- Easy to install

- Utilizes many standard guardrail components

Side of road where a recommended clear zone and recoverable slope is attainable.

X-LITE SYSTEM SPECIFICATIONS

- Classification – Redirective Gating (R-G) End Treatment

- Length – 11.4 m / 37’ 6″

- Width – Tangent or Flared

- Height – 710 mm or 790 mm / 28″ or 31”

- Straight / Variable Flare – 1.2 m / 4’

- Test Level – NCHRP 350 TL-3

Portable Lighting

Ver-Mac’s PSLT-4000S is a compact and powerful portable solar light tower that is cost-effective and has a great return on investment. It is visually as bright, effective and compact as conventional diesel light towers, without costing thousands of dollars every year in fuel and labor. The PSLT-4000S features 4 LED lamps with Ver-Mac’s exclusive Nightbrite technology, which provides a brighter and more environmentally-friendly lighting system. The PSLT-4000S is ideal for lighting construction work zones, parking lots, special events, emergency response and oil and mining applications.

PSLT-4000S FEATURES AND BENEFITS

- Nightbrite technology – Innovative exlusive LED fixture design provides 40% increased brightness using the same power consumption, compared to other solar light tower systems.

- Clear and Bright LED lamps – Long lasting and durable LED lamps provide targeted lighting with minimal light pollution and reduced glare..

- Compact Design – The innovative solar panel and trailer design make the PSLT-4000S easy to transport and set up without taking up valuable space..

- Intelligent Controller – Schedule and control the brightness and length of your lighting event. Ver-Mac’s easy-to-use selector switch provides multiple brightness and timing settings.

- Power platform – Robust power platform combined with energy-efficient Nightbrite technology makes it autonomous for weeks in most applications!

- Low cost of ownership – Eliminate fuel, fuel labor, engine maintenance and sodium light replacement costs and save thousands of dollars per year.

- Multi-Orientation Solar Panels – Solar panel tilts to various positions to maximize the performance, without having to move the trailer around.

- Environmentally friendly – No fuel emissions and engine noise to harm the environment

GENERAL SPECIFICATIONS

- LED lamps: 4 adjustable fixtures

- Luminosity: up to 42K lumens total

- Batteries: 470 A/h wired in a 24-volt system

- Battery charger: 40 amp

- Solar panels: 295 watts total / tilt up to 30°

- Mast: 20 feet (painted orange)

- 2 outriggers for trailer stabilization